Thank you for your interest in my Knives! |

My goal with Blue Knives is to create the best knives that I possibly can. I simply refuse to cut corners with the materials, design or craftsmanship of the knives that I make. |

||||

|

|

Pattern Welded "Damascus" Steel. Damascus Steel is made from four types of high carbon steel that have been forge welded together, twisted and manipulated to form a beautiful 412 layer steel billet. In ancient times, before modern metallurgical techniques, Damascus steel was used to create blades that were both hard and tough. Modern Damascus steel is created by layering alloy steel to achieve this same layered effect. |

Why is Damascus Steel So Expensive? Damascus steel is extremely difficult and time-consuming to make. The creation of a Damascus billet can take just as long as the rest of the knife making process. I will only use the highest quality Damascus steel available and each piece has been meticulously hand-forged by master Damascus makers in the USA. I will not use cheap imported imitations. |

|

52100 Carbon Alloy Steel 52100 steel is not stainless steel, it will develop a grey patina with normal use and can rust if not properly cared for. 52100 is used in many industries to make bearings. It is a favorite steel for many of the worlds top knife makers, but the complicated heat-treating process makes it too difficult and costly for mainstream knife factories to use. |

|

|

Wood |

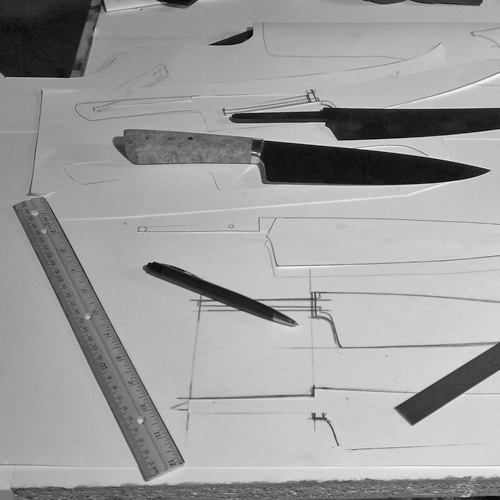

| My distinctive handle design is based on a fusion of the best elements from many traditional knife handle styles. It incorporates the curved, ergonomic advantages of a classic European knife handle with the formal simplicity of a Japanese style handle. |

Many knife companies use the design of their knives to save money during the manufacturing process. Unfortunately this almost always results in a knife of inferior functionality, ergonomics and aesthetics. Some of the most common shortcuts are: |

Blade Thickness |

| Steel Quality Almost all factory knives are made of stainless steel. This makes it easier for uninformed or careless customers to keep the knife shiny but reduces the functionality of the steel as a fine blade. I work with only 52100 steel, and do all of the heat–treating by hand in order to maximize the potential of the material. |

Handle Shape |

|

My name is Alex Blue. I am a Knife Maker and Designer living and working in Seattle Washington. I have been making knives since graduating from the Rhode Island School of Design with a degree in industrial design. I have always enjoyed creating things with my hands. Knife making combines many of my interests: design, craftsmanship, and business. |